IQF (Individual Quick Freezing) kiwifruit processing line is a kind of equipment system specially used to process fresh and ripe kiwifruit into quick-frozen products. The main feature of this line is that it can quickly freeze kiwifruit in a very short time, so as to retain its original color, flavor and nutrients to the greatest extent.

IQF (Individual Quick Freezing) kiwifruit processing line is a kind of equipment system specially used to process fresh and ripe kiwifruit into quick-frozen products. The main feature of this line is that it can quickly freeze kiwifruit in a very short time, so as to retain its original color, flavor and nutrients to the greatest extent.

IFQ Kiwifruit Processing Process

The typical IQF kiwifruit processing process includes the following steps:

- Raw material sorting: Use kiwifruit sorting machine to screen the fruit by size and maturity; select fresh, ripe, disease-free and insect-free kiwifruit as raw materials.

- Washing: Use professional fruit and vegetable washing machine to remove surface impurities and pesticide residues;

- Peeling: Use mechanical or chemical methods to remove the skin of kiwifruit to ensure that the peeling is thorough and the loss of pulp is minimized.

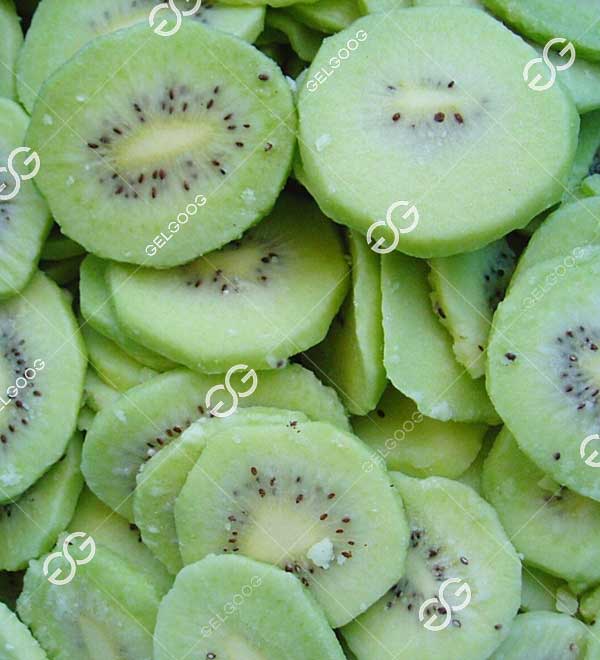

- Cutting: According to product requirements, cut kiwifruit into slices, blocks or wedges, and the cutting process needs to be fast to reduce oxidation.

- Blanching and cooling: In some processing processes, kiwifruit slices or blocks need to be blanched to inactivate enzyme activity, and then quickly cooled to room temperature.

- Quick freezing: The kiwifruit is sent to the IQF quick freezer and quickly frozen in a low temperature environment of -35℃ to -40℃, so that each fruit slice or fruit block is frozen independently

- Packaging: The quick-frozen kiwifruit is weighed and packaged in a low temperature environment, usually sealed in food-grade plastic bags or boxes.

- Storage and transportation: The packaged kiwifruit is stored in a cold storage below -18℃ to ensure that it remains frozen during transportation and sales.

IQF (Individual Quick Freezing) kiwifruit processing line is a kind of equipment system specially used to process fresh and ripe kiwifruit into quick-frozen products. The main feature of this line is that it can quickly freeze kiwifruit in a very short time, so as to retain its original color, flavor and nutrients to the greatest extent.

IQF (Individual Quick Freezing) kiwifruit processing line is a kind of equipment system specially used to process fresh and ripe kiwifruit into quick-frozen products. The main feature of this line is that it can quickly freeze kiwifruit in a very short time, so as to retain its original color, flavor and nutrients to the greatest extent. Features Of IQF Kiwifruit Equipment

Features Of IQF Kiwifruit Equipment